PROOFS OF CONCEPT

The proofs of concept within the project aim to structure the research undertaken in each pillar of the COAMSYS project and ensure visibility of the research within the socio-economic world. Thus, each proof of concept incorporates concepts developed within the four pillars and the methodological framework. They also serve as a training opportunity, allowing students to work on projects and internships, and provide the material support for the doctoral theses undertaken within the project.

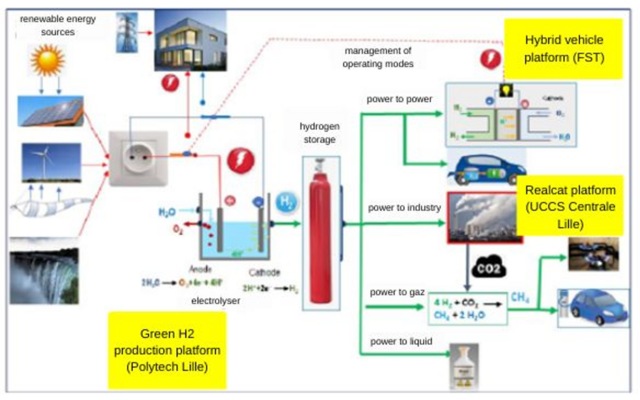

Two proofs of concept have been identified: the first one focuses on the hydrogen chain, from "green" production to utilization, including storage, electrolysis, fuel cells, and hydrogen-powered vehicles. The second one relates to a micro-energy generator system based on multiple energy recovery and storage, aiming to power specific sensors. This second proof of concept can be installed within the vehicle of the first one to provide monitoring or assisted control for instance.

Proof of Concept #1 – Hydrogen Chain: From Renewable Production to Vehicle Utilization

The main goal of this proof of concept is to showcase the technological advancements of the project in all stages of green hydrogen production, storage, conversion to electricity, utilization in an embedded system such as an electric vehicle, energy management, and supervision.

The research activities focus on resolving technological and fundamental challenges such as:

- The optimal management of intermittent renewable energy sources such as wind turbines or solar panels to ensure energy availability.

- The study of technical feasibility (upscaling validation) for the industrial design of electrolyzers (multiphysics modeling).

- The implementation of online algorithms for health management and prognosis (predictive maintenance) of green hydrogen installations, the valorization of green hydrogen (power-to-power) through PEMFC and SOFC fuel cell stacks.

- The production of new fuels through catalysis (DME) (power-to-gas).

Furthermore, the energy management of electric and hybrid-powered vehicles (PAC + batteries, supercapacitors) represents a crucial hurdle to overcome in terms of real-time optimization of vehicle dynamics, as well as its range and even its lifespan. These research topics are already the subject of interdisciplinary work carried out by CRIStAL, UCCS, and L2EP.

The multi-source energy platform, already employed in Master projects (SMART FST U-Lille, Polytech), will be utilized in conjunction with other platforms such as Realcat and "e-V" for Master-level training within the framework of the Graduate School (Institut d'Ingénierie Lillois) and in areas such as "H2 Production Systems," "Fuel Cell Usage," "H2 Molecule Applications," "Control and Safety," "Renewable Energies," "Electrified Transportation," etc.

This first proof of concept will consist of a renewable electricity generation platform generated by wind turbines and/or solar panels.This electricity will be used to produce hydrogen through low-temperature water electrolysis. The produced hydrogen will be stored either in gas bottles or in recharge stations developed within the project, for later use in low-temperature Proton Exchange Membrane Fuel Cells (PEMFC) or SOFC-type fuel cells. The electrical energy will thus be available at any time for use in the transportation and/or tertiary sectors.These fuel cells will be tested in a hybrid vehicle with PAC and batteries and/or supercapacitors, with energy management optimized according to various criteria.

In a different context, the green hydrogen produced by the electrolyzer will be used together with carbon dioxide to produce Dimethyl Ether (DME) at Realcat (UCCS, Lille central). In this field, collaborative work is being developed with UCCS.

Renewable energy sources and the electrolyzer will be incorporated into the green hydrogen production platform (Polytech Lille). Following hydrogen storage, the "power to power" dimension will be overseen by the Hybrid Vehicle Platform (FST). The "power to industry", "power to gas" and "power to liquid" dimensions will be included in the Realcat Platform (UCCS, Centrale Lille).

Proof of Concept #2 – Micropower

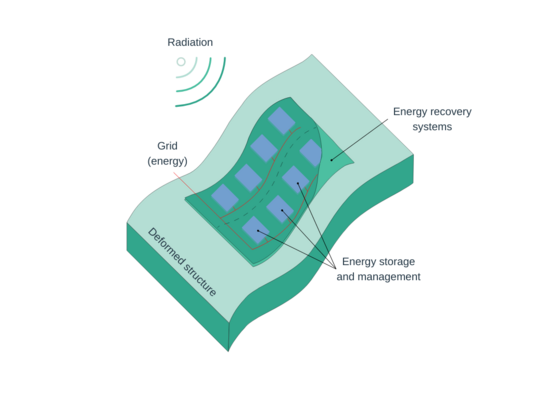

The goal of this proof of concept is primarily to showcase the viability of multi-source energy harvesters, which involve combining at least two distinct energy sources: harnessing energy from electromagnetic waves, structural deformation, or thermo-electric effects. This necessitates the successful fabrication of intricate structures, such as multilayers, with each layer intended for utilizing a specific energy source. In this context, we are focusing on flexible and large-scale substrates, an area of research currently pursued by UMET, IEMN, and GEMTEX researchers.

It is also essential to seamlessly integrate the storage device into the system. In this case, a discreet yet distributed storage solution is envisioned to maintain the flexible nature of the micro-generator. Ensuring that the storage elements are sufficiently small, with a high volumetric energy or power density, is crucial to avoid compromising the recovery capacity of the generators. The energy management of the entire system becomes a critical consideration, requiring the exploration of solutions that enable both global energy management at the level of the harvester and the implementation of specific management laws for each storage element. This energy management will be derived from a system model. One challenge lies in the practical implementation, particularly when dealing with low power levels to be converted. It is imagined that the power generated at each element would be on the order of 100µW.

Therefore, this second proof of concept takes the form of an "active skin" that encompasses all aspects of energy harvesting: the harvester, the storage, and the energy management. Resulting from interdisciplinary collaboration, this proof of concept will provide a versatile and adaptable energy recovery solution, suitable for various scenarios such as powering sensors integrated into clothing.

Radiation is shown at top left, above the active skin, which consists of a deformed structure, with a central network (energy), sensors for energy storage and management, and a section dedicated to energy recovery.